Over the decades, plenty of project management styles have emerged. Some of them were aimed at improving production and workflow, while others have their roots in different places. Earned value management is one of the latter.

While it began as a financial analysis method, it evolved into one of the most useful project management methods to date.

In this article, you can read about the basic elements of earned value management, how each of them contributes to the grand scheme of things, how to integrate the earned value management method into your production process, and some common misconceptions.

What is earned value management (EVM)?

What is the meaning of EVM? To clarify the phrase itself first, earned value and earned value management are two different things.

Earned Value is the value we assign to work – it can be expressed in hours or in monetary units (dollars, euros, yen, etc).

Earned Value Management (EVM) is a technique, or a method, used to help project managers assess the costs of labor on a project, and predict project performance. It compares the planned out roadmap (both financial and workflow-related) and the actual production progress.

It takes the traditional project management approach a few steps further and improves upon it to provide precise data – for project managers, clients, and employees alike.

Another term worth knowing (as it’s often used along with those two) is Earned Value Analysis (EVA). According to wbdg.org, earned value analysis is “an industry-standard method of measuring a project’s progress at any given point in time, forecasting its completion date and final cost, and analyzing variances in the schedule and budget as the project proceeds.”

As a core principle, EVM exists to answer three important questions on every project:

- Where were we?

- Where are we right now?

- Where will we be / Where are we going?

Earned Value Management focuses on three important data sources:

- The planned value (initial budget for the project)

- The actual value of the finished project

- The earned value of the work that was completed

Using these three sources and matching them against the project timeline, we are able to capture the work’s progression. That way, problems, hurdles, and successes are spotted on time.

When to use earned value management?

This method was developed to follow very large projects with bigger budgets that want to avoid the most common pitfalls – going over the budget, missing deadlines, and under-delivering. However, simpler EVM solutions work for smaller companies as well.

For companies that already use a time tracking tool and have their project management methods, but still need more discipline and structure, EVM could be the solution.

Let’s take a simple example:

You are hired by a client to do a project in a year and are given $100.000 to complete it. You split the finances evenly across deadlines. Every three months you should have spent a quarter of the finances. Fast forward to three months later, and $25.000 dollars of your budget was used up, as planned. This can give you the impression that everything is going well.

The deadlines continue, you spend your budget evenly, and by the time the project is over, you’ve spent all of it, as planned. However, as you review the final product, you realize it’s only 70% finished! Taking a closer look, you find out that back in the first quarter, instead of having 25% of the work completed for your $25.000 budget, you’ve only done 20%. Three months after starting, you were already behind schedule, and it only kept piling up!

How does EVM help in this situation?

Without keeping an eye on the work completed at those deadlines, you can reach the end of the project only to realize too late that it had cost your client more. On the other hand, you can have a situation where you’ve spent $25.000 and finished 30% of the project, which puts you ahead of schedule. Which would be great news for the employees and the client.

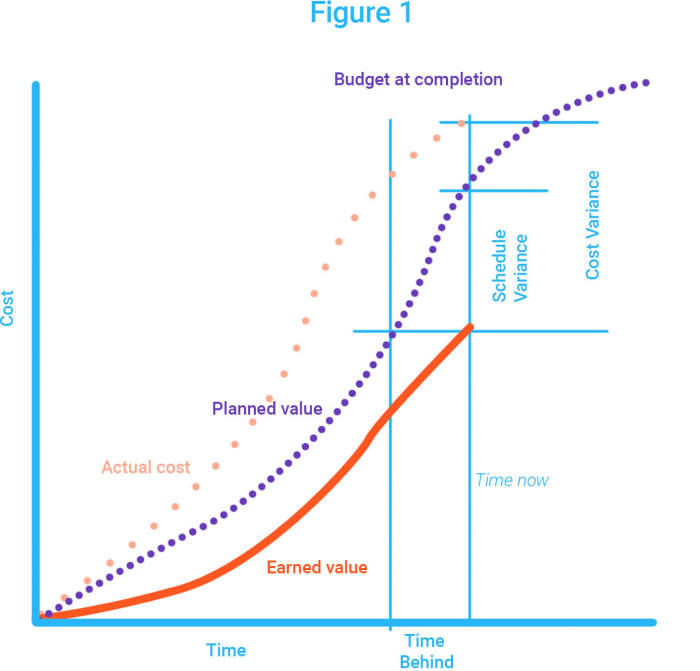

Graph 1: EVM is best readable on a graph

Why do you need earned value management?

Earned value management is cost and schedule control method. But there is potential for it to become more than that – it can strengthen the production process of the project, mitigate failures and signal incoming problems, so they can be bypassed timely and effectively.

There are different upsides to EVM, even depending on the side you are looking at it from.

Contractor benefits of earned value management::

- Creates a solid performance framework;

- Provides solid risk management;

- You can accurately measure and see the project’s progress at any stage;

- There’s a single system that tracks time, work done, and the budget, instead of multiple;

- Forecasts the completion date and expenses by the end of the project.

Client benefits of earned value management::

- Informs which projects and/or agencies are worth investing in;

- It’s easier to be provided with more accurate reports;

- Greater transparency;

- Tracking the progress of the project in near-real-time makes for more informed choices on further funding.

Make no mistake, earned value management is beneficial to every field of work. But as we’re about to see, there are a lot of moving parts that can make EVM a bit of a hassle for tackling.

The basic elements of EVM

Even though this methodology adapts to the industry it is in, the core of EVM are these four elements:

- Work Breakdown Structure (WBS) – the foundation of your project

- Planned Value (PV) – the budget given to realize the project

- Earned Value (EV) – the value created by the project in production

- Actual Cost (AC) – the cost of the work during the realization of the project

Yet, in this article, we would like to add one final important element to the Earned Value Management – the Control Account Manager.

And here’s why.

Plenty of project managers make the mistake of tacking on the EVM task onto an employee who already has something on their plate. This overburdens the person, as the method is complex and taxing with all the data that needs to be tracked and calculated. Assigning the role of a control account manager as a side-role will only yield inaccurate results every time. In order to get any value from EVM, you will want someone who can devote complete attention to it.

Now, let’s see what makes each element of EVM important.

1. Work breakdown structure (WBS)

Work breakdown structure is a step-by-step representation of the entire work on a given project. This document contains everything from the description of the tasks, the milestones, the hierarchy of the tasks, and its connection to project deliverables. As a foundation document, it is crucial for the EVM’s success. As its name suggests, it breaks down the project into units of work, so that they can be assigned, scheduled, authorized, measured during production, and cost-accounted. The complexity of every WBS will depend on the scope and complexity of the project itself.

Before getting into EVM, it is recommended to brush up on your skills in estimating work time. Clockify can be a handy tool in achieving this precision.

2. Planned Value (PV)

As the Project Management Institute states, Planned Value is “the authorized budget assigned to work to be accomplished for an activity or WBS component.” In simpler terms, this value tells you how much of the budget is supposed to be spent on each step of the project. PV is usually calculated at the very beginning while determining the budget and assigning costs to labor. But it is also welcome during production, as it helps reveal how close you are sticking to the budget plan.

For example: You have a project that spans over 10 months. The budget is $100,000. After 5 months, you’ve estimated to have 50% (half) of the project done. What you want to know is how much of the budget would be spent by then?

PV = (Planned completion %) x (BAC)

PV = 0.5 x 100,000

PV = $50,000

This means that the planned budget expenditure for this stage of the project should be $50,000. When you compare it to the Actual Cost (AC) of the work at this stage, you can find out if you are going over budget, or if there’s room “to breathe”.

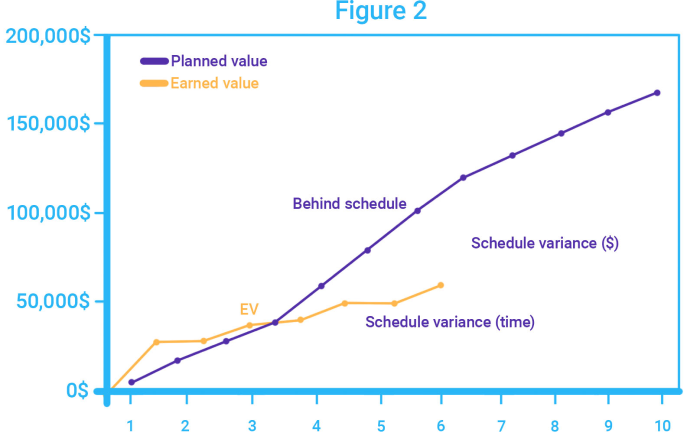

3. Earned Value (EV)

According to the Project Management Institute, the definition of Earned Value is “the value of work performed expressed in terms of the approved budget assigned to that work for an activity or WBS component.” Again, in simpler terms, EV reveals the value created from the work done so far.

For example: Using the same data from above, we again have a planned budget of $100,000 and 10 months for completion. After 5 months, you realize that only 30% of the work has been completed. How much value has the work actually garnered?

EV = (actual completion %) x (BAC)

EV = 0.3 x 100,000

EV = $30,000

Reading the results, you would expect that the project will earn $50,000. However, the math shows its value as much lower. So, had you only followed the planned value curve saying you’ve spent half the budget as expected, you might be fooled into believing everything is okay. But with the added earned value you get the real picture of being behind schedule.

Graph 2: The Earned Value (EV) curve reveals a schedule delay.

Calculations like these show that the budget and schedule are not separate elements of production. Once we start looking at them in conjunction, we can avoid big mistakes like this.

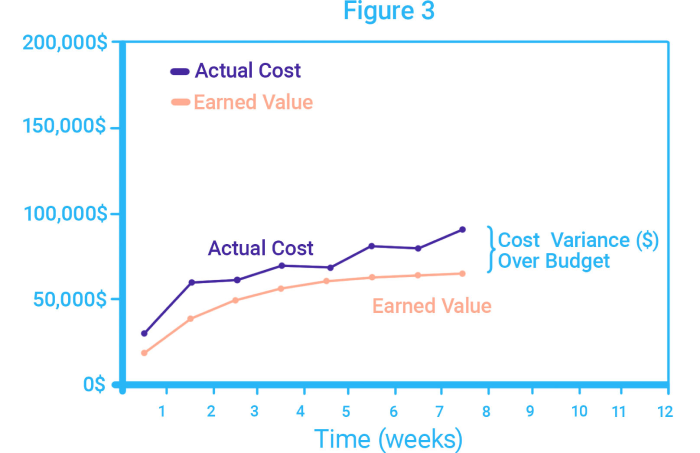

4. Actual Cost (AC)

The Project Management Institute defines Actual Cost as “the total cost actually incurred in accomplishing work performed for an activity or WBS component.” It is the real cost of the work done on the project at any given time.

Unlike the other two values, AC doesn’t have any formulas for calculation, since you can clearly identify it. That information is always readily available. Taking the above example, you notice that instead of the Planned Value of $50,000, your company had actually spent $60,000 after 6 months. With these results, you’ll know that some loss mitigation and rescheduling are necessary.

Graph 3: The Actual Cost (AC) curve is much higher than EV, showing the project is over budget.

5. The Control Account Manager (CAM)

To avoid overburdening a project manager with additional EVM tasks (that also need a fair amount of research), it’s advised to appoint a Control Account Manager (CAM). Since Earned Value Management is a complex and multi-layered method of tracking project progress, it is best to have someone dedicated to this task only.

Furthermore, this is the only way you actually see the benefits of EVM, as it will be more than a project manager’s afterthought, or a side-task. So, who exactly should be your control account manager and what will their duties be?

Who should be a CAM?

A control account manager is not someone who writes reports, tracks data, and then gives rapport. This person will have complete control over monitoring the production, the costs and any changes made that will affect the budget. For these reasons, a control account manager needs to be a person who is accountable, responsible, and authoritative.

They will have to manage the costs and the budget, and direct resources depending on where they’re needed the most at that moment. Additionally, CAMs are an important part of client meetings, as they have all the information needed for performance and project reviews. They supply the clients, project managers and employees with the data most important to them.

What is in a CAM’s job description?

There are a lot of responsibilities a control account manager undertakes. While they will vary from industry to industry (depending on the scope of work and types of projects), the general ones include:

- Preparing and maintaining the control account plan, along with the budget and costs;

- Monitoring the budget, and schedule, and reviewing activities;

- Analyzing the variances between the budget and the schedule to spot possible problems;

- Developing recovery plans for any schedule or cost variance;

- Approving and reviewing all work assignments, all commitments, and documents related to the control account.

To reinforce the argument of how important a control account manager is, the next section describes just a handful of the obligatory measurements used in EVM. There are formulas CAMs use to track progress along with the production, and they range from the basic ones used on smaller projects, to more complex and detailed ones required for large-scale projects.

Now let’s take a look at the basic calculations the CAM needs to make to accurately track your production progress.

Calculating variances and indexes to follow the progress in EVM

Variances are the actual indicator of how well a project is doing concerning time, budget, and the work performed. The difference between what was planned and the project’s actual progress can reveal if the work is behind, or ahead, if your budget is depleting faster, or if you’re generating more money than expected.

The basic formulas to calculate variances need the three previously established key values – Earned Value (EV), Planned Value (PV), and Actual Cost (AC).

With them, you can calculate performance indicators and important variances that show if you are behind or ahead of schedule, and under or over budget.

These are called schedule variance, cost variance, schedule performance index, and cost performance index.

This is how they work:

Schedule Variance

Schedule Variance formula: SV = EV – PV

This variance shows if you are ahead or behind schedule.

If the SV is positive, you are ahead of schedule . If it is negative, you are behind, and if it equates to 0, you are right on schedule.

For example: As we’ve seen above, our earned value is $30,000, while our planned value was $50,000. According to the formula:

SV = 30,000-50,000

SV= – 20,000

Since the result is negative, it means the project is behind schedule.

Cost Variance

Cost Variance formula: CV = EV – AC

This variance shows you how over or under budget you currently are.

A negative result signals you’re over budget, while a positive result means you’re under budget.

For example: In our established example, we’ve seen that EV is $30,000, while the AC is $60,000. To calculate the cost variance you would apply the formula in the following way:

CV = 30,000 – 60,000

CV = -30,000

The value of your project at the current state is lower than the money spent on it, bringing you way over budget.

The cost and schedule variances give a general idea of where you currently stand with the project. To identify precisely how much the project is behind, or over budget, you use performance indexes.

Schedule Performance Index

The formula of Schedule Performance Index: SPI = EV / PV

This index will show how close the project is to its completion when compared to the schedule.

If the result is greater than 1,the project is doing well ahead of schedule. Less than 1 means it is behind, while equal to one means everything is according to schedule.

For example: Our EV is $30,000,while our PV is $50,000. Using the formula we get:

SPI = 30,000/50,000

SPI = 0.6

Which translates to: For every hour of work on the project, the team is completing 0.6, which is a little over 30 minutes.

Cost Performance Index

The formula of Cost Performance Index: CPI = EV / AC

This index shows how budget-efficient the project is.

If the result is higher than 1, the project is doing better than planned. If the result is 1, everything is working according to the planned budget, and if it is less than 1, the project is over budget.

For example: Using the values above, we can do the following:

CPI = 30,000 / 60,000

CPI = 0.5

As we’ve seen in Cost Variance before, the project is over budget.

Note: These four formulas are the ones most commonly used in EVM, because of their applicability to any project. Depending on the industry you work in, and the scope of the project, you can find other, more specific formulas.

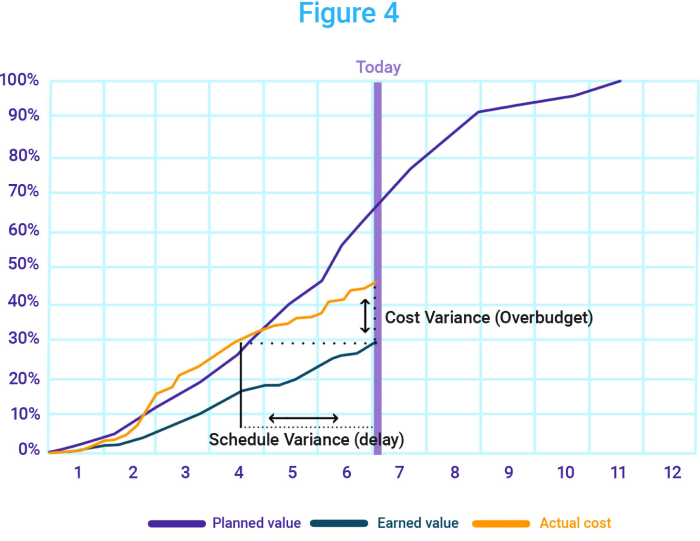

Graph 4: All three values on the same curve showing actual project progress.

Interested in implementing EVM in your projects?

With so much as a spreadsheet and a project time tracker, even smaller companies can achieve the same as larger ones do with specialized software. So keep reading, as we are about to break down its basics, its integration, and the mistakes to avoid.

Four steps for EVM implementation

The following section presents four steps for the implementation of an earned value management system into any project. Take note, however, that this is a lightweight version of the methodology, as it has varying degrees of complexity depending on the industry, the scope of the project and the skill level of the team.

For smaller companies and projects, as well as those who look to understand EVM, this breakdown will prove to be more than useful.

Step 1: Make a work breakdown structure (WBS)

The first stage is dedicated to organizing the team on the project. You formulate the work breakdown structure (WBS), which is used to determine the scope of work and break it down into units. Look at it as the skeleton of the entire project. Every single bone should be accounted for.

This is also the moment where you familiarize the team with each work unit. Together with them, you should decide on how long each task would take to be finished.

Step 2: Scheduling and setting milestones

After you’ve divided the project into individual steps, it’s time to schedule them. The best way to go about this is to arrange them so the tasks flow into each other as naturally as possible. They should be codependent, in that lower-level tasks support higher-level ones and aid in reaching the larger milestones. That way you avoid having “straggler” tasks that are left behind because they don’t have a place in the grand scheme of the project.

Taking the Planned Value, you allocate the total budget across all of the tasks and determine the milestone budget expenses.

When it comes to breaking down projects into tasks, it can be much easier than you think.

Step 3: Define the Earning Rule

The “earning rule” (also known as the 50/50 rule in project management) is, in short terms, how much of the allocated credit for a task will be paid out upfront and on its completion. There are several earning rules:

- Credit is paid out only upon completion (0/100 rule),

- Credit is paid in half at the beginning and half upon completion (50/50 rule), or

- A small amount at the beginning and the rest upon completion (20/80 rule).

Although you can vary these rules depending on the type of task, it is advised to stick to a single one, for clarity. Nowadays, more CAMs decide on the 20/80 rule over the previously popular 50/50 rule, because the emphasis remains on completing a task rather than just starting it.

Step 4: Execute the project according to WBS and track the progress

As the project moves along, the CAM is tasked with following along as the tasks are started and finished. Using the earning rule, they accumulate the earned value (EV) either weekly or monthly. The thoroughness of the EVM method also allows them to follow the projects in near real-time, meaning that CAMs can also accumulate EV on a day-to-day basis. In fact, doing so might prove more beneficial for project-tracking, evading risks and damage control, than a monthly accumulation.

Advanced implementations require additional elements, like establishing control accounts to delegate authority and responsibility to different parts of the organization. They employ more detailed values and indexes to track the progress as accurately as possible. In these versions of EVM, the processes are more elaborate in order to have better control of baseline revisions, and require integrations with EVM systems. Overall, there is much more preparation, more materials to include, and additional software to use.

Limitations of earned value management

Naturally, no methodology or system is perfect. And while earned value management answers the call for plenty of companies that want more structure in their production, it’s far from ideal. Should you decide to implement it, here are the limitations you should keep in mind.

1. Earned value management leaves little room for mistakes

The biggest concern with EVM is that unless it is used precisely and along with the project, you will not get accurate results. Additionally, unless the different aspects of EVM (budget, schedule, and workflow) are tracked or reported on in time by authorized persons, by the time you get the necessary data you could be days or even weeks behind. EVM requires an effective and accountable team, and that everyone is on the same page.

2. EVM doesn’t offer quality control

The second limitation causing concern is that this methodology doesn’t include quality control. Since its main concern is work performed, the time of completion and the cost of it, there is no room for quality. A product could be delivered in time and with an admirable budget, only to fail to impress by the end of production. Or worse, a problem arises when poor quality of completed tasks starts to affect all the subsequent tasks and slows down production.

3. Earned value management is not a quick and easy solution

The third limitation lies in EVM’s complexity. Just like with the Agile method,there is no quick and easy way to start implementing it and see stellar results on the first run. This methodology requires an experienced senior team that will break down its introduction into the company. After that, it will take some time for everyone to adapt, which leads to a lot of trial and error.

4. There is a risk of micromanagement in EVM

Since everything is constructed to work like clockwork, there is a risk of creating a rift between the management and the employees themselves. Those involved with the big picture are unable to delve into the concerns and workings of those executing the tasks, and vice versa. For this reason, EVM should be treated lightly and implemented carefully.

With these in mind, you can approach EVM’s introduction and eventual implementation with more caution. Be mindful of the possible pitfalls your company could fall into before introducing EVM.

What are the common EVM misconceptions?

Decided to dip your toes in earned value management? Unless you devote enough time to it, odds are it will project results that are constantly a little off. There are many instances where project managers pick out what they believe to be the core points of EVM and use them for their projects.

For this reason, we’ve set aside some common mistakes and misconceptions those unfamiliar should be aware of.

Misconception #1: Only large corporations and big projects can benefit from EVM.

It is true that, historically, mostly large companies and institutions had benefited from earned value management. However, as we’ve shown above, basic/light versions of EVM are available. A smaller company can achieve the same result with small alterations.

Misconception #2: EVM will prevent budget issues and deadline delays.

Make no mistake, EVM can bring so much structure and discipline to your overall production. However, its main selling point is its role as an early warning system. It relays information crucial for avoiding risks and reveals if there is enough room/budget for revisions and delays.

If you are worried about deadline delays and want to combat them, you should practice time management. With a time tracking software like Clockify, it’s easy to develop a rapport habit and perfect this skill first before introducing something like an earned value management system. This will minimize the odds of small mistakes that can have greater repercussions.

Misconception #3: You only need the appropriate EVM software to be EVM ready.

We cannot stress it enough how the system alone doesn’t work without a person attached to it. The software is there to help make the lives of CAMs, shareholders, project managers and all those involved easier. It is not a replacement for a skilled team member devoted to tracking the project’s progress.

Misconception #4: Only the project manager and the control account manager should trouble themselves with EVM.

Everyone, from employees to shareholders should have access to some aspect of EVM. Unless everyone on the project understands the importance of the work breakdown structure and all its moving parts, the whole method collapses. Reports will be inaccurate or late, task completions delayed, and so on. To get the most out of earned value management, everyone needs to understand the importance of following the WBS and the rules.

To Conclude

Earned value management is complex as it is beneficial for projects of any scale. Its scope, systems, terminology, and materials are abundant with information that caters to every industry.

That being said, this article had covered only the general information, with the aim to bring it closer to the reader. It presented the key values and metrics at the core of every EVM strategy.

To get a better understanding of how you can apply EVM to your production process, we recommend further research and education. So long as you are open to trial and error and keep a willing and diligent team, you can implement it easier than expected. Best of luck!

✉️ Have something to add about your experience with earned value management? Let us know at blogfeedback@clockify.me to be featured in this or future posts.