Measuring employee productivity can bring vital changes to how a company operates. It positively influences both the micro (employee) and the macro (company) level of work. We want to offer you an in-depth guide that addresses:

- The importance of measuring employee productivity

- Which methods and metrics to use, and

- How methods vary depending on individual companies

What is productivity in business

Productivity can easily be misunderstood for efficiency in production.

Production is the quantity of output based on the input. So calculating how much output you get based on the time, resources, and money invested is actually not productivity.

Productivity is how efficiently the resources, money, and time are being used to produce the output. As a basis to go off of, the following is the formula for measuring employee productivity:

Output/Input = Productivity

Input

Input is the number of units (labor, work hours, energy, money) invested in producing an item or providing a service.

Depending on the industry, the input can be anything:

- Kilowatts of power (with operating machinery)

- Hours worked (jobs where payroll is calculated per hour)

- Volumes (pounds or kilograms)

Output

Output is the number of items/goods produced or services provided, based on the amount of input.

For example, a designer puts in three hours of work to produce five drafts for a company logo.

By the formula, it comes down to:

5 drafts/3 hrs of work = 1.6 drafts per hour

Or, you can calculate productivity based on how much a business earns per hour in a given timeframe:

$120,500 worth of goods/1,730 hours = $69.65 ($70) per hour

Or how much every individual employee contributes to the output. You would use the same earnings, just divide them by the number of employees:

$120,500 worth of goods/45 employees = $2,677 per employee

While the formula itself is straightforward, it needs some expansion when we apply it to the modern workplace. And here is why.

Where the waters get muddied

Measuring productivity is never as simple as using the output/input model.

Frederick Winslow Taylor, a 19th-century mechanical engineer, began analyzing productivity ever since he himself was a manual worker.

He observed productivity as a progression in one’s skill. For example, a fisherman on a boat, who uses a net to catch fish. Firstly, Taylor would watch and analyze every step of the process, and find those that could be eliminated. So-called “time wasters”. Stripping away those unnecessary steps, and leaving in only the essential ones helps the fisherman be more unburdened and productive.

Secondly, he would argue we can find a way to redesign his tools – fix the boat, or find a better one, get a sturdier net, etc. And surely, the fisherman would be even more productive. As Peter F. Drucker explains in his paper, historically we’ve seen this method work for hundreds of years. Eliminating unnecessary steps and improving workers’ tools does increase productivity. And it’s continuing even now: just compare personal computers from 1995 and the ones in 2020 – and what the PCs of today can do for the average worker.

But what happens if we try to apply the same method to, say, an HR worker?

Do the redesigned, improved tools make for better output?

Are they able to reach out to more people in an office?

Which begs the question – is HR’s productivity calculated in how many employees they talk to in a day, or how well they help them with their issues? What do we measure?

To accurately measure and improve productivity, you first need to discern whether your company does manual work or knowledge work.

Manual work vs Knowledge work

Manual work focuses mainly on quantity while aiming to achieve the minimum quality requirements. It’s mostly seen in plants, factories, assembly lines… any kind of mass production. The worker is provided with tools and the know-how, employing skills they already know. And those same resources they get are left behind once they leave the company.

Knowledge work focuses on quantity and quality equally. Some examples include education (number of students isn’t as important as the knowledge they transfer), health (doctors, nurses, lab technicians), and more. While they are given tools to work with, knowledge workers are responsible for their own learning, skill sharing, innovating, and are given more autonomy. And when they leave a company, the knowledge they gained goes with them.

And since pure manual work can be measured with a straightforward formula like the one above, knowledge work contains more factors that need to be addressed. To keep this article reasonably short, we will only be looking into knowledge work.

Then, what are good metrics to measure employee productivity?

How to measure productivity

As we’ve mentioned, the core of knowledge work is reflected in one question:

“What is the task?”

For a project manager, the task can be something different every day. One day, they spend most of their time answering emails, contacting clients, and attending office meetings. While the next day, they could be analyzing project progress, changing deadlines, discussing further steps with department leads, and more.

For a store clerk, it seems like the task is already known – sell products. However, they also have to stock shelves, round up the money at the end of the shift, do paperwork concerning restocks, receive shipments, clean up,…

So, to accurately measure productivity, Drucker claims it starts by asking the following:

- What is your task?

- What should your task be?

- What setbacks make your tasks more difficult?

- Which steps should be eliminated?

Only when an employee reflects on these questions can they start to shed the unnecessary steps that impede productivity. These answers will help them find ways to go about certain problems, helping in productivity increase.

1. The labor productivity method

The labor productivity method measures a company’s productivity and efficiency based on the formula for estimating output per employee.

Depending on the type of labor being performed, labor productivity can be measured by using three different methods:

- Partial labor productivity,

- Multifactor labor productivity, and

- Total labor productivity.

Let’s go over each method in more detail so that you can select the most suitable one for your business.

Partial labor productivity

This method uses the simplest productivity formula we’ve mentioned above – the ratio of input to input.

It calculates and shows the ratio of a single input, for example, how many hours it takes to design a logo. Labor hours are the most common input, simply because it is the key aspect of the economy and employee productivity. Other inputs are:

- Manpower/labor

- Energy costs

- Materials used

- Capital/Financial

Businesses sometimes prefer the partial labor productivity method, because it calculates one input independently of the collective, the data is easy to interpret, improve, and compare to other industries. So, our design team lead could compare their designer’s three-hour output to other designers of the same caliber.

But, at the same time, it doesn’t show productivity in the context of the whole performance, which can give misleading results.

Multifactor labor productivity

This productivity method calculates output in relation to labor and capital, since those two are usually treated as the most important inputs.

Output/(Labor input (hrs worked) + Capital input ($ invested)) = Multifactor Productivity

Multifactor productivity helps you identify output taking more important inputs into account. This is also how productivity is calculated on a national level. However, it still leaves out other inputs, so you can never get an accurate picture of overall company productivity.

Total labor productivity

Lastly, total labor productivity incorporates all of the above inputs into the formula:

Total output/All inputs (materials + labor hours + energy + capital + other expenses) = Total Factor Productivity

The Total output in this method concerns all tangible values of the output, not just the monetary value or number of items/products/services. It includes:

- Number of finished products

- Dividends

- Interest, and

- Other income

This method is excellent when a company needs to see its overall productivity, but it proves to be difficult to compute, for one, and also can’t pinpoint how much each individual input affected the productivity. So one would need to gather additional data for more precise readings.

2. The hours worked method

Labor hours seem to be the most common unit of input when calculating employee productivity. The modern workplace requires workers to take on tasks that aren’t necessarily the focus of their job description. Remember the designer example?

In their case, other responsibilities would include attending brainstorming sessions, stand up meetings, answering emails, monitoring new recruiters’ progress, etc. They are hardly just researching and designing the company website and illustrations. And the higher up they climb, the responsibilities shift.

So measuring hours worked seems to be the most reliable way, as employees are also paid per hour.

The hours worked method has three subcategories: productive hours, units per hour, and hours per unit.

Productive hours

To measure productivity through productive hours only means you will focus only on the time employees spend on the tasks they were given. The only way to accurately collect this information is to employ a time tracking system.

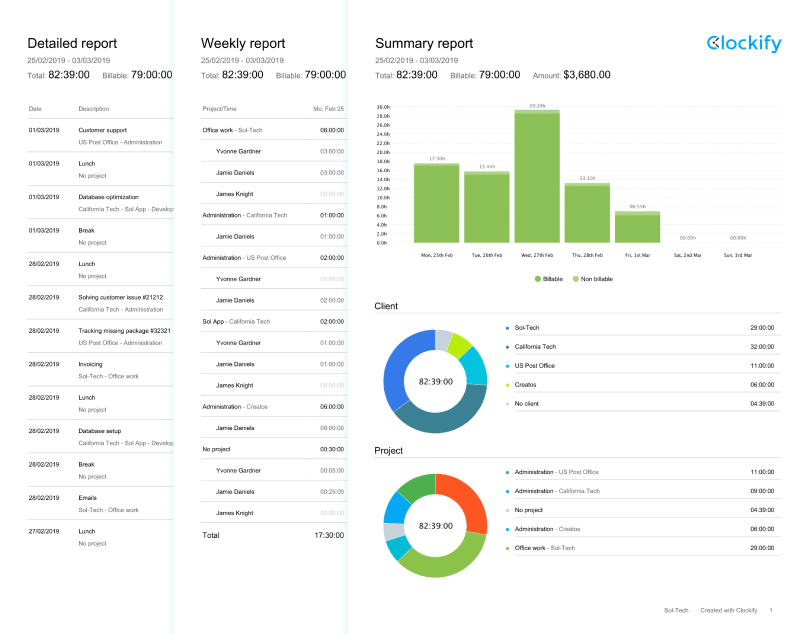

You introduce a company-wide time tracking software and have people start to time themselves on each important task. Certain products, like Clockify by CAKE.com, let them label each task to an appropriate category (bug fixes, Jira, meetings, report writing, etc). And you can filter these labels to see how much time was spent on specific tasks, vs time spent on those that don’t contribute to the project progress.

The tagging system in Clockify shows which tasks get the most or the least time.

Tagging tasks can provide for really detailed productivity reports, so long as they are accurately used. You can find guides on the topic here:

Units per hour

Again, to be able to use the productivity formula, we should decide what we use as input and output.

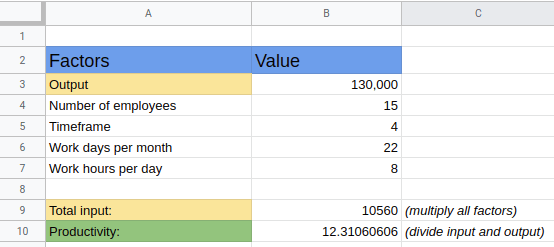

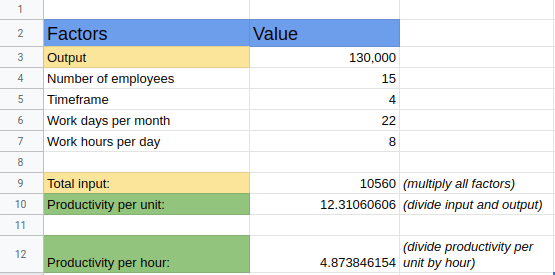

For example, a company had generated $130,00 dollars in products in four months. It took 15 employees, 22 workdays a month, and 8 working hours per day.

The output is $130,000. The input is the accumulated hours it took the employees to generate that revenue. So, we need to calculate the input first. The calculation will go something like this:

Our defined output is 130,000, but to find out how many hours it took to produce the capital, we need to multiply the values of all factors. The result is 10, 560 hours to make a product.

And to get the productivity value, we need to divide the two values. We can then see that 22 employees produce 12,3 units per hour in the span of 4 months

This kind of calculation is usually used by complex manufacturing companies, like Sony, Volkswagen, Siemens, Bosch, etc.

Units per hour

And to calculate how many units employees make per hour, we simply have to reverse the above productivity formula.

If they make 12,3 units per hour, then we would have to divide 60 minutes by 12,3.

In the knowledge economy, this formula is applicable if you want to calculate, for example, the number of sales calls each salesman makes per hour, or in telemarketing and customer service.

It is also suited for smaller manufacturing businesses, and jobs like docking, loading, food processing, etc.

💡 If you are interested in trying out the calculator for yourself, you can find it here.

How to adapt the productivity formula

We’ve said that the knowledge economy has multiple factors it needs to account for. Employees don’t have “just that one task”. Most will have tasks that aren’t entirely in their job description, which will affect their productivity.

So how can you accurately calculate it, while being mindful of the different factors?

Create a baseline

To be able to analyze the results, you first need to create a baseline – the reference point against which you will measure your productivity results.

That means comparing your acceptable, expected costs (how much money, energy, manpower, hours goes into production) to the real results.

In the example of our designer, 1.6 drafts per hour could be the expected productivity level for their manager – the baseline. However, if the baseline is, say, 2 drafts per hour, then the manager could say the designer is underperforming.

Here are the specific steps to adapt the output/input formula to your own needs:

Step 1: Determine your input

Decide on what aspect of productivity you want to assess. That determines your input.

It can be labor hours, units produced, productive hours, cost per hour, etc.

Step 2: Determine your output

The output is the end result: the final product. It can be a marketing project, client acquisition, successful sales in a month, revenue, etc.

Step 3: Apply the formula

After deciding on the values of input and output, simply use them in the basic formula, and calculate the result.

Output/Input = Productivity

Step 4: Compare it to the baseline

When you get the results, compare them to what you’ve determined is a productive level. It can be the number of hours worked, or the amount of resources/money spent in producing one part of a product, and so on.

Depending on the factors you are including, the calculation can become a little more complex, like in our examples above.

3. Measuring productivity aside from numbers

While not a productivity measurement in its own right, analyzing productivity through objectives can be far more useful than bare numbers. Especially in the knowledge economy.

Because of the numerous aspects affecting one’s productivity, we can’t rely solely on numbers. So, in addition to the formulaic approach, you will want to employ one (or more) of the following methods:

Measuring through time management

The most widely-used method of measuring employee productivity is how well they manage their time. Whether they take more or less time on specific tasks, how much time is spent on menial things, or wasted. The studies conducted are astounding, and reveal a lot about our habits.

Something as simple as a timesheet can give you a great overview of the entire team and each employee’s contributions to the overall production.

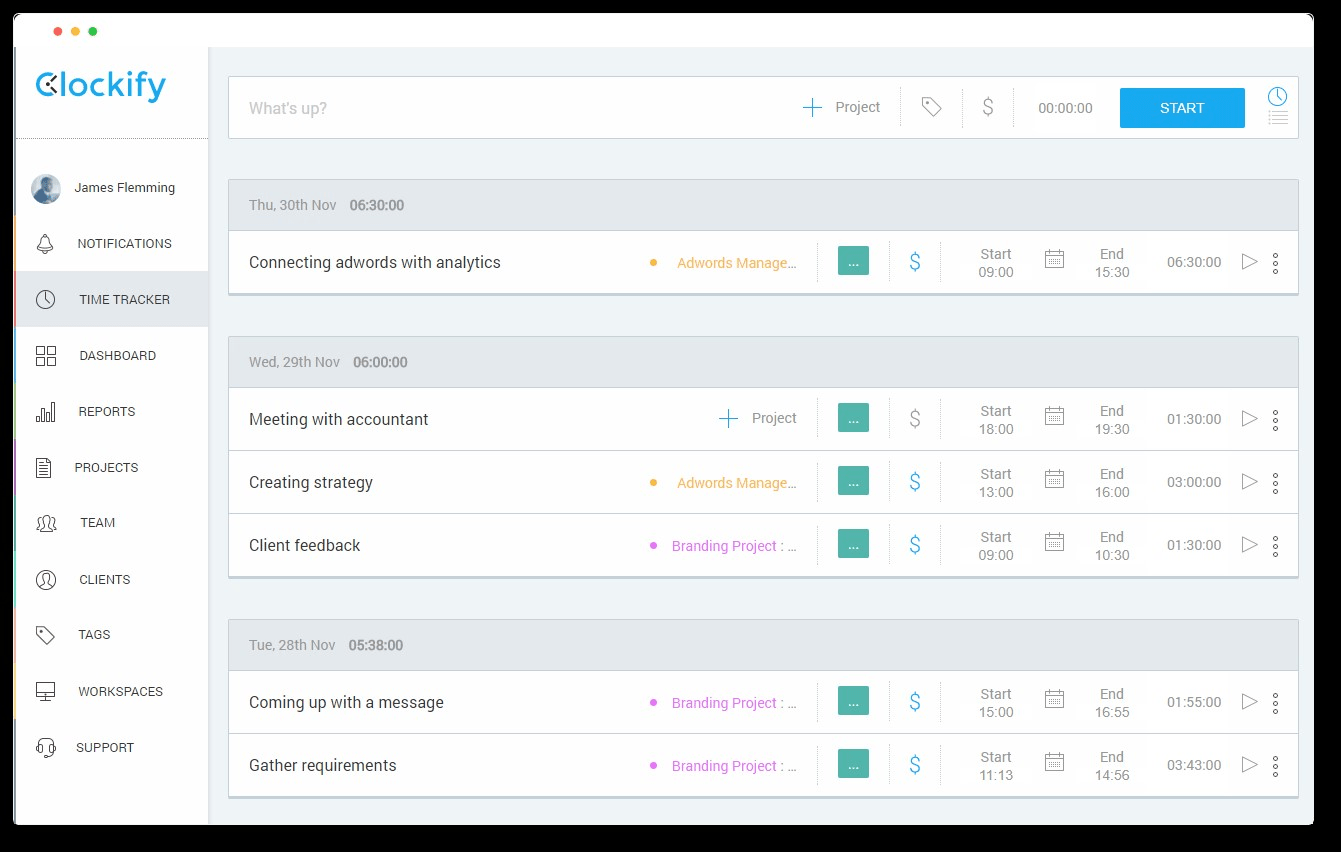

Here is an example of an individual and team timesheet in Clockify, and a generated report based on the time tracked metrics.

With a digital time tracker, you can assign employees to a project, and let them track time on each of their tasks. They can even label them, so you can easily follow on which aspect of the project they’re being more productive. Likewise, you can see where they’re encountering hurdles, and address them in time.

💡 Here’s an in-depth guide on employee time management you can provide to employees.

Measuring through goals set

Two companies within the same industry can be equally productive and successful but still have wildly different methods.

One can focus on breaking new ground, building better products, taking risks by innovating. This keeps their customers engaged and waiting to see what’s next.

The other works on improving already existing user experience, perfecting their services and making it more accessible to a wider audience. Moemen Ahmed of Gleeds Construction Consultancy gave a great example with BMW and Toyota:

“Both companies are well established with a long heritage of success, however, each of them implements a totally different strategy.

Toyota is pretty famous for its ‘Total Quality’ strategy, which tends to focus on providing the widest visible market with a product that holds all the required functionalities with excellent quality and for a feasible price for most consumers. Toyota has led and pioneered this kind of strategy, especially during the 1980s and 1990s and proved to be very successful to deliver its promises to consumers all over the world.

On the other hand, BMW is a company that strives to implement high technology and extra functionalities to its consumers. BMW strategy focuses on delivering a top-notch product that offers the consumer prestige and luxurious experience for a relatively high price. BMW doesn’t target a wide slice of the total car market, instead, it focuses on top-notch sectors only.”

Studies have shown that employees who are aware of their company’s overarching goals are much more productive. They feel more connected, and get a sense of purpose and place within the company structure. To measure productivity from setting goals you can try to:

- Set milestones that push the organization closer to the goal

- Set smaller deadlines, achievable chunks of time for each department

- Observe the employees’ workload management

- Meet with

In the end, you could use the productive hours calculation to see the time it took to reach the milestone.

However, you can achieve the same without formulas – if the milestone has been reached, you are on the right track. But if it wasn’t, you can start identifying the issues in every department and find ways to bring them back on track.

Measuring through objectives

With this method, you can see how each employee’s output contributes to the larger-scale operations of the company.

One reliable way is to use performance evaluations. They are methods of tracking and observing an employee’s overall job performance, and can range from attendance tracking to inter-office relationships and agreeableness. Ultimately, it gives you an idea of employee productivity on a more empirical level.

The measurements are largely descriptive, use specific objectives, and rely on regular 1:1 evaluations (every one, three, or six months). We’ve written an archive on performance tracking, that we feel can be useful when using this method.

- Why and how to create performance standards (with examples)

- How to track employee performance (with templates)

- How to calculate and rate employee performance

- Performance review: 6 common methods

Measuring with the 360-degree feedback

This kind of measurement relies on gathering information from the coworkers of a specific employee. The first known use of this method was by Esso Research and Engineering Company back in the 1950s, and since then has undergone numerous adaptations and changes.

However, the core idea stays the same: a person’s productivity is evaluated by people they work with on a daily basis. And not just from their own departments.

Some are concerned this method can be unreliable. One can never know how objective someone’s coworkers can be, and what’s more, assess them based on their work performance only. Fortunately, we’re making strides in fixing this issue by providing appropriate training for 360-degree feedback.

Lastly, it’s recommended for small businesses only, as their employees will have more collaboration and contact opportunities.

It is crucial to decide on a cut-off period where you can assess if the method is working out for you. Additionally, you will be tracking the changes in market and customer demands, because the economical landscape changes every so often, no matter the industry.

Reevaluating your methods and adapting them every six months to a year (even earlier if needed), is a good way to keep on track with productivity measurements. Because if the labor costs get cut, your target customers change, or resources grow exponentially, they will all largely affect how the work gets done.

What affects employee productivity within a company?

Now we will take a look at some of the departments within a company (IT specifically), and all the factors that account for their productivity levels.

To get firsthand experience, we’ve interviewed a few of Clockify’s team leads for their opinions on measuring productivity, and how they approach it.

Customer support

First off was our own customer support lead, Jovana Kandić, on how they observe productivity, and the factors that are measured and analyzed:

“Generally, productivity in customer support is measured by the number of tickets resolved, first resolution time, first reply time,… And that’s just concerning the tickets. We also look at the number of accepted chat messages, missed or dropped calls percentage, average response time, and the like.

It’s highly measurable, because we have a lot of metrics, but there’s also the risk of losing the core point in all the data.”

This is another point in favor of a more empirical approach to measuring productivity where possible. Relying on numbers too much can hurt employees, especially when outside factors aren’t taken into account.

Human Resources

We have also asked Biljana Rakić, head of HR at Clockify, for her take on the topic:

“We do look at quantitative values, like how many employees we’ve approached for consultation and evaluation in a month, for example. But we also take into account the overall satisfaction, and how many trainings and courses we can provide within a year.

Additionally, we monitor and measure the recruitment process – the number of candidates contacted, the response rate, and the like. We’ve also started including satisfaction surveys, where potential candidates can rate the experience with the HR representative.”

Programmers

Lastly, our lead programmer, Ljubomir Simin, shared his two cents on how he handles productivity metrics:

“Well, on the one hand, you have quantifiable metrics – like the number of code commits, or operations on GitLab, source control activity (number of changes, reviews, etc). The data is kind of synthetic, but provides a baseline.

On the other hand, there are result-driven metrics – did the person meet the deadlines, how many bugs were there, etc. I personally prefer measuring productivity based on larger deadlines, when they concern more major features that we want to implement. Smaller tasks, like the ones you do several per day, have very little impact, really. However, we evaluate all of it in some form or another during performance reviews.”

Why you should measure employee productivity

Now, all of this information begs the question: is calculating employee productivity and analyzing all that data really worth it?

Large-scale benefits of measuring productivity

1. Better utilization of resources

As mentioned before, productivity is the result of how well resources and skills are utilized to produce an output. Knowing how your employees work, what software they use, and how they communicate with coworkers can all give you an idea on where your resources are underused or if you need to introduce something new.

You will know whether to get new software, provide additional training and courses, if there’s too much overtime, etc.

2. Identifies unnecessary steps

Remember the example with the fisherman, from the beginning? Productivity is all about conserving employee’s energy to help them focus on tasks that matter. They shouldn’t expend it on tasks that can be eliminated, or performed by others.

Unburdened employees are more productive, happier, and eager to work harder (not more, though – so don’t use this opportunity to add to their workload!).

3. Reduces cost on all levels

When you calculate productivity based on the ratio of output to capital invested, over time you can see where to make budget changes. Maybe some processes cost you more than necessary, which you wouldn’t be aware of without the productivity data you’ve gathered over a course of time.

The same goes for the costs of time, energy, and manpower.

4. Keeps you adaptable to the market

It’s like keeping a finger on the company’s pulse. When the market changes, so will your company’s strategies to keep up with the demand, competitors, and trends. The employees could suffer under pressure and increased or altered policies.

Keeping track of their productivity through an established method can signal problems much earlier, before any permanent damage.

5. It reflects system performance

When you’re aware of the productivity levels of your employees, in time, it will show how well your system is functioning. It will be easier to implement changes, and you will know exactly when, where, and how, and with no detriment to the company. No time lost, no financial losses, either, and less stressful transitions.

Individual benefits of measuring productivity

1. Less wasted time

The reasons for wasted time can be many. However, one of the biggest factors always seems to be social media, longer downtimes during breaks, delaying finishing tasks and so on. Measuring productivity can reveal these pockets of inactivity, and how often they occur.

While you can turn a blind eye to some wasted time if it happens infrequently, too much of it can cause heavy procrastination, which results in rushed work and stress because of impending deadlines. And most employees aren’t even aware of how much time they spent browsing mindlessly!

As you track their time and analyze the reports, you can use this data to explain how this deceptively short distraction adds up a lot. Whether they are aware or unaware of it, the employees will start being more mindful, and together you can even set objectives to lessen their browsing time.

2. Productivity increase

An established system for analyzing productivity streamlines people’s work ethics. Knowing their work is being evaluated and rewarded accordingly, they are more likely to feel fulfilled and motivated to work harder.

More satisfaction at work leads to less stress and fewer turnovers for the company.

3. More skilled employees

As mentioned earlier, the results of productivity measurements can timely point out gaps in workflow and accurately identify the reason for it. While many of them can be factors that are out of your control (family matters, money issues, mental or physical health, etc.), those you can see and control are lacking skills or direction.

You can fix this by organizing proper training, perfecting specific skills, providing reading materials or mentors to help bridge any gaps in knowledge.

4. More driven employees

Measuring productivity means you can evaluate your employees more frequently. This is an opportunity to remind them of the company’s direction, and let them know their role in it. Thus, you’re helping them form professional ideals and objectives that can align with those of the company.

It lets them feel less like a cog in a machine, and more like an integral part of the picture.

Lastly, productivity coach and author of The Productivity Zone Penny Zenker makes a case for determining what you consider productivity, and how knowing those can make or break a productivity improvement plan. In this interview, she talks about managing energy, why shorter deadlines can be better, and how productivity methods need to be adapted to each individual person.

Clockify by CAKE.com can be your ally in measuring employee productivity

Measuring employee productivity is important for businesses and employees as it provides the necessary information, such as:

- Productive work hours,

- Employee output,

- Employee input, and more.

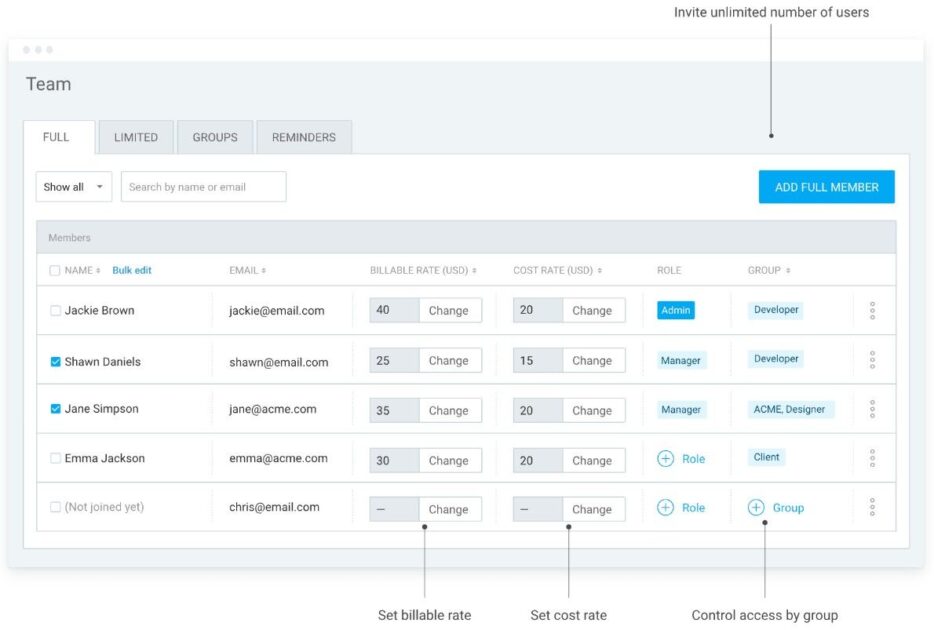

To measure employee productivity, you will need a time tracking system that can show how your workers allocate their time versus how much time they spend on each task.

Enter Clockify by CAKE.com.

As an all-in-one time tracking software, Clockify allows you to track work hours, projects, tasks, breaks, and much more. Once you create a workspace in Clockify, you can invite your team members, and they can start logging their work hours.

As you schedule tasks and assignments for your team members in Clockify, you ensure everyone is well aware of their tasks and responsibilities. Of course, this fosters accountability.

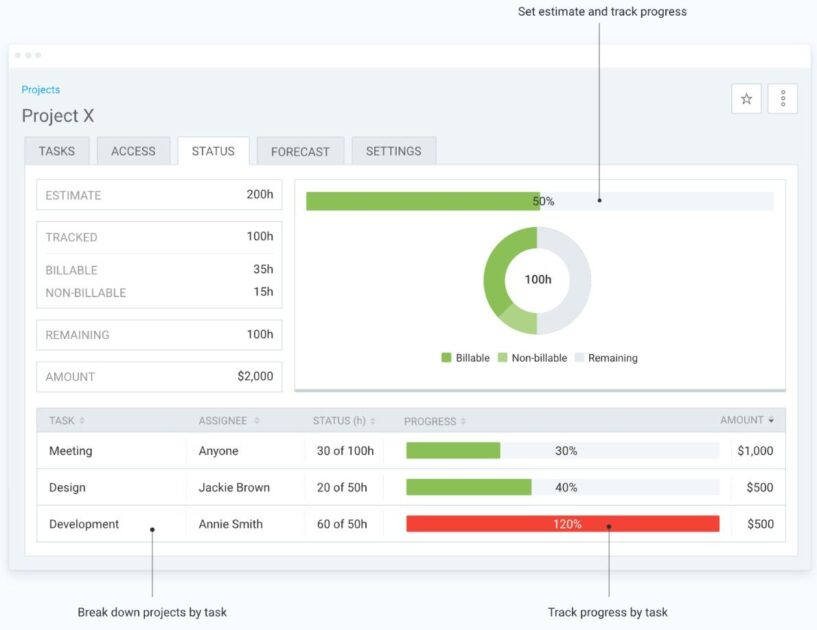

Moreover, once you and your team members start tracking time, you can track project progress directly in Clockify. Here’s how you can access the Status tab:

- Click on Projects in the menu on the left side,

- Select a project from the list, and

- Choose the Status tab.

The Status tab gives you a plethora of information about the project you selected. For example, you can view information such as:

- Time estimate (remaining vs. tracked time),

- Billable and non-billable time,

- Expenses (billable vs. non-billable),

- Tasks and assignees, and

- Amounts.

Clockify is there to help you boost your team’s performance and measure employee productivity in a stress-free way.